The Problem with Checklists

How modernizing an old tool made a world of difference.

Checklists are the most common and useful tool in any process – personal or professional. Whether you’re packing for vacation, managing a production line change, or even hosting a Van Halen concert, your checklists make sure you don’t miss anything critical.

A critical oversight is exactly what led to the first commercial use of a checklist in 1935. Boeing mandated their use after a test flight turned deadly. The pilot had forgotten to do a simple task which ended with several people injured and two dead. 1

Today, business process checklists, in the form of SOPs, are just as critical. They can also have similarly devastating consequences if they’re not followed.

Despite their prevalence, most companies still deploy checklists using the same technology that was used in 1935. Even companies that use AI in their supply chains or robots on their manufacturing lines are still equipping their employees with pencil and paper to perform their most critical tasks.

We’ve all become accustomed to paper checklists that appear posted next to workstations, in binders, on paper handouts, and on whiteboards. The problem with distributing checklists this way is the complete lack of accountability that comes with it. We can’t expect our people to follow One Best Way processes if the tools we provide them are inaccessible during work or easily ignored.

Bringing the checklist to the 21st century

Acadia brings checklists and accountability into the hands or your team members as they perform any critical task. Here are six steps we use to help our customers improve.

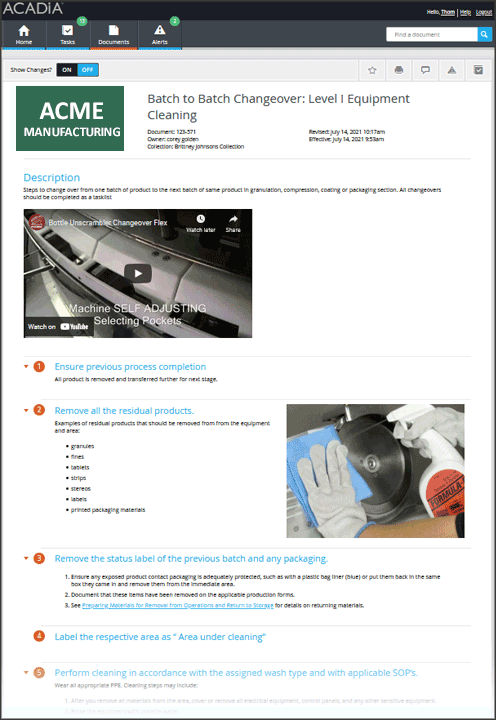

1. Your One Best Way business process is easily accessible to the person who needs it – instantly, on any internet-enabled device.

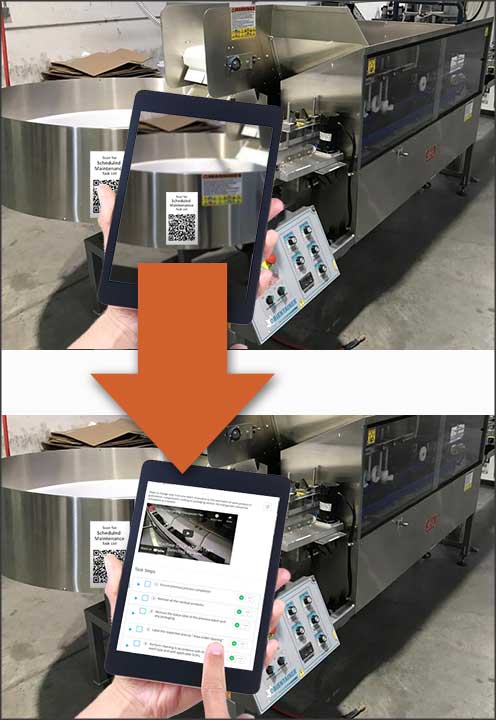

2. The process, in the form of a checklist, is self-assigned using a QR code, distributed as part of a work order from your ERP, or assigned by a manager.

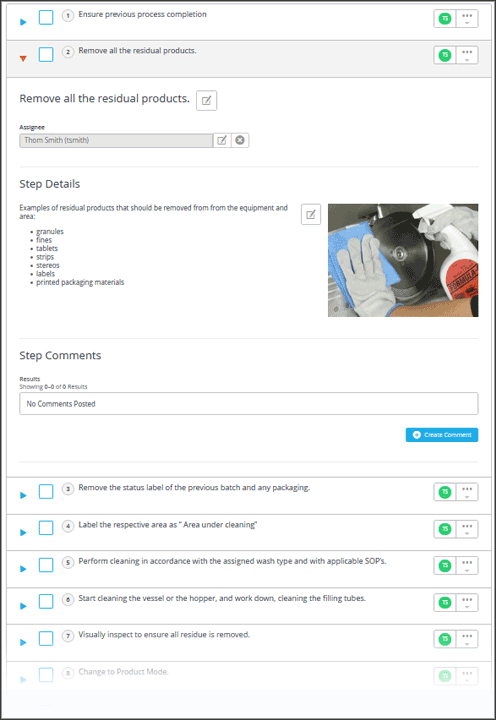

3. Each task in the checklist is simple, easy to follow, and includes relevant job aids.

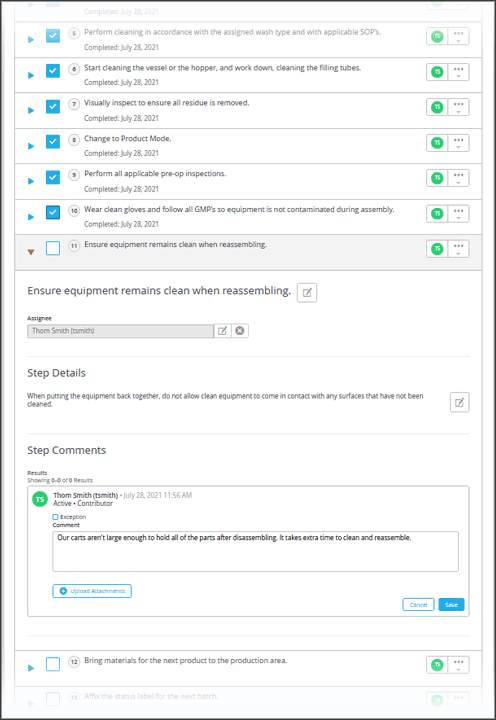

4. When a task is performed, it is recorded, time-stamped, and attributed to the person who completed it. This works even if task lists are split between people or across shifts.

5. Those performing the tasks are empowered to identify roadblocks that prevented them from completing the task. They can also suggest process improvements during workflow.

6. All data generated during process execution is correlated to operational KPIs. This creates actionable insights that help you identify who needs more training or what processes need improvement.

These tools are process agnostic, so they can be (and have been) applied to just about any workflow.

Below are just a few examples where Acadia has been put to work. If you don’t see one that relates to your business, give us a call, we have tons more we’d love to share.

Cleaning and sanitation

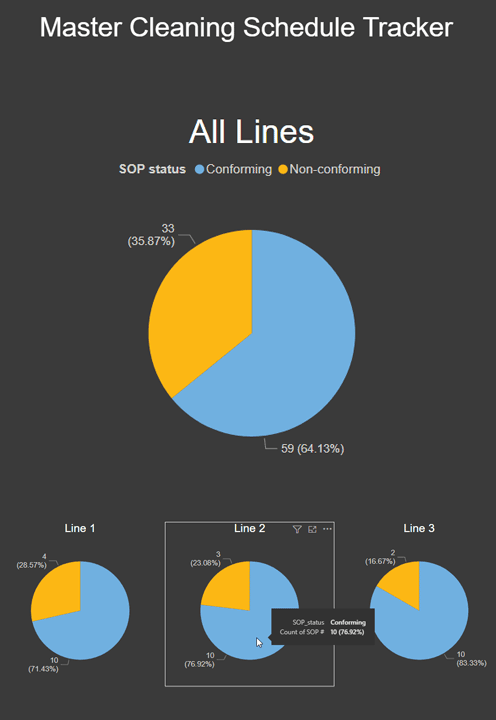

The weekly line cleaning and sanitation process was a major undertaking for one of our manufacturing customers. It was complex and difficult to track until they modernized it with Acadia.

Previously, the business process manager for each production line would manually manage their team’s execution of the weekly cleaning schedule. The manager would print out daily checklists and distribute them to the teams responsible for performing the sanitation procedures.

Some team members followed the SOP to the letter. Others skipped steps or did things their own way.

At the end of the shift, the manager would collect the checklists, mostly dirty and tattered, and enter the results into a spreadsheet. It was a huge manual effort and, at its best, only captured the results of the team members who used them honestly.

When not used properly, the process was prone to errors resulting in safety issues, blocked product, lost time, waste, and damaged equipment.

Now the process is way more efficient. The business process manager’s manual process has been eliminated. Sanitation SOPs are assigned to the employee(s) responsible for completing them. They scan a QR code on the device that needs to be cleaned. The process is completed step-by-step and anything that can’t be completed properly is flagged to the manager. Things that weren’t done, or weren’t done properly, are easier to identify. Then they can be fixed before causing damage to people, products, or equipment.

New Process Training & Deployment

New Process Deployment at a warehousing customer was time consuming and became a lag on on-time delivery improvements. Just distributing SOPs to the workforce took an average of 614 hours!

A major obstacle in their process execution was the use of paper-based SOPs and paper-based compliance. SOPs were produced and distributed to staff on paper. Managers recorded, also on paper, which employees received the SOPs. Then the results of those reports were entered into an electronic system to ensure all employees received the correct documents. Even then, the company couldn’t tell if employees were following the SOPs, and team members couldn’t provide feedback to improve the procedures.

After converting their paper procedures to digital documents in Acadia, any new or updated SOPs could be delivered to the relevant employees with a few clicks. The system itself could identify when all employees had received them. Managers can now audit employees for compliance and provide additional training to those who need it.

In less than six months, the company blew by their target goal for distributing SOPs, reducing their process change training time by 90%. More importantly, they improved outbound orders shipped on time from 40% on average to 80%.

Order to Cash

A large enterprise customer has grown by merging with and acquiring other large firms over many years. This left the company with many overlapping and sometimes conflicting business processes. Without an internal, single source of truth, they couldn’t speak to customers with a single voice.

Team members in sales and finance had multiple sources of information – binders, SharePoint, emails from managers, etc. – to guide their contracting and billing processes. So, there was a tremendous amount of confusion around which instructions to follow and under what circumstances. This meant there was massive expense from inefficiencies, major deals were lost, cross-selling opportunities were missed, and customers were frustrated.

By standardizing and optimizing business processes in Acadia, they were able to create a unified customer experience across all touch points. They reduced confusion through standardization and enabled employees to learn while doing.

As a result, Order-to-Cash operations improved across 12 regional shared services teams including a major decrease in billing errors and rework among their largest, national accounts.

They were also able to improve customer service and response time by centralizing One Best Way desk instructions for customer service staff.

Process improvements like these didn’t happen overnight. But what would have taken years with pencil and paper came together in months with Acadia. It’s possible to create and sustain behavior change in your organization. You can eliminate confusion while improving the business metrics that are most important to your success. You just need the right tools.

Here’s a 2-minute overview of the whole system

Sources:

"*" indicates required fields

Ready to crush your goals?

"*" indicates required fields