Your processes are only as effective as your weakest link

Overcoming the hurdles standing in the way of our best business processes, Six Sigma projects, and CI initiatives

- Human error is responsible for 23% of unplanned downtime in manufacturing

- Businesses lose at least $62 billion per year through poor customer service

- Repeated exposure to critical training information helps ensure employee compliance

- Identifying team members who make the most mistakes and equipping them with better training and job tools can eliminate breaking points where processes fail

In 1986, in the 10th inning of Game 6 of the World Series, the Red Sox held a 5-3 lead against the New York Mets. The Mets hit three consecutive singles, driving in a run and leaving runners on first and third.

Outfielder Mookie Wilson came to the plate and was at a count of 2-2 when Bob Stanley threw a wild pitch. The runner on third came home to tie the game and put the winning run in scoring position. Wilson reached a full count and after a handful of foul balls, hit a slow bouncer up the first base line.

It should have been an easy third out. Bill Buckner just had to scoop up the ball and touch first base. The Red Sox would have had another chance at bat and the opportunity to close out the series. Instead, the ball dribbled through Buckner’s legs and into the outfield. The player on third ran home, scoring the winning run, and sending the Series to a seventh game.

The Mets won that one too, prolonging Boston’s legendary dry spell and cementing Buckner’s error as one of the worst in baseball history.1

This story is paraphrased from a much longer narrative from Bill Buckner’s obituary in The New York Times. Though a series of unfortunate events had really led to the loss, the blame was placed at Buckner’s feet and followed him throughout his entire life until he died in 2019.

Thankfully, most of the mistakes we make at work won’t haunt us for the rest of our lives. But when individuals regularly fail to follow our One Best Way protocols, the efficiencies we would have earned bounce right between our legs into the outfield.

The mistakes that ruin our efficiency

Human error is responsible for 23% of unplanned downtime in manufacturing.2 Similarly, businesses lose at least $62 billion per year through poor customer service, a rate that has been rising exponentially every year.3

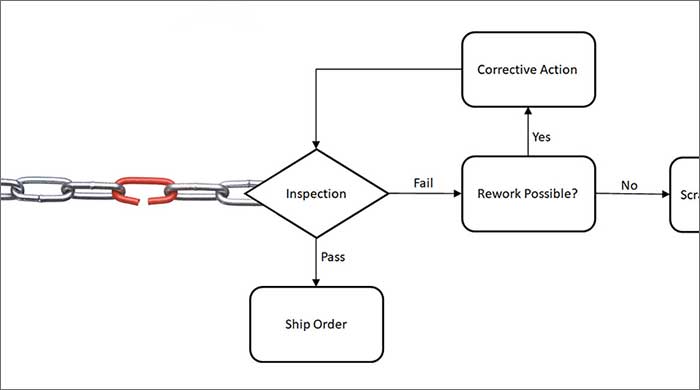

It’s impossible to eliminate all mistakes from our workflow. What we can improve is SOP compliance, eliminating repeat mistakes that cause injuries, waste, and inefficiency.

Assuming our team members aren’t intentionally undermining our processes, the blame for lack of compliance likely lands squarely on those of us who implement them.

Common reasons people don’t follow protocol

- They don’t know it

- They haven’t been properly trained

- Someone else showed them a different way

- They don’t have the resources needed to do it correctly

- They think they have a better way

Fortunately, all of these issues can be addressed with a few simple tools.

Training Gaps & Job Aids

Most people don’t learn well in a classroom or using LMS courseware alone. Those training methods can help to introduce processes, they just don’t provide the hands-on experience needed to cement correct behaviors in place.

Repeated exposure to the same information used in initial training helps bridge the gap to hands-on activity. Consider converting your protocols into checklists that can be followed as work is completed. Incorporating videos, diagrams and other visuals into checklists can further help to connect the dots.

The benefit of a simple checklist was quickly apparent for one of our clients. They began by requiring employees to follow digital SOPs in the form of checklists on just one of their product lines. The visibility and accountability that followed drove SOP compliance. The company was also able to tie SOP compliance to improvements in several KPIs. Using this success as a benchmark, the company then deployed the same method across all of its North America operations. After deployment, all Acadia-enabled plants using checklists for 6 months or longer exceeded their gross line yield target for the year.

Feedback (taking it, not giving it)

Fixing training gaps and making team members accountable to a process helps remove a lot of weak links. But what about the team members who think they have a better way to do it? How do we get them to comply? Sometimes the best way to create behavior change with these folks is to listen to them.

The people who do their part of the process day-in and day-out have an infinitely more granular view into what works and what doesn’t. If you make it easy for team members to suggest improvements, while they’re performing tasks, they’ll identify more actionable process improvements than you could tease out with other methods. Deploying their ideas will give employees more buy-in too and change their behavior to further embrace the process.

This played out in real-time on the very first day Acadia went live in one of our clients’ plants. After the PM had gone home for the evening, his night shift submitted feedback on multiple tasks. The most impactful feedback involved a packaging machine with a worn part that was creating frequent jams. Each jam meant the machine had to be shut down, cleared and restarted.

The employees didn’t want to have to deal with the jams, but there wasn’t a clear method to escalate the issue. So, they just cleared them and went on with their work. When the problem was identified, a solution was quickly worked out. Seeing quick changes made it clear to the team that their feedback wasn’t landing on deaf ears and the plant continues to see process improvement suggestions come in regularly.

A Rising Tide Lifts All Boats

The team members who make the most mistakes are the most likely to lose their job and the most likely to have trouble getting a new job.

They need your help to succeed through better training and better job tools. But helping these folks isn’t an act of benevolence or altruism. This is where your processes break down and where your KPIs go to die. Helping them makes your entire team more efficient and productive.

By identifying the folks who regularly don’t follow your One Best Way processes, you can eliminate a major breaking point where processes fail. Look deeper into what drives some of these behaviors and you’ll find ways to help your team members overcome them.

Sources:

Ready to crush your goals?

"*" indicates required fields