You’ve fought hard to remove cost from your processes

Here’s how to keep them from sliding back in

- Waste doesn’t just happen on the frontline. Replacing old tools can help beyond the frontline.

- Old habits and ineffective tools can prevent permanent change from sinking in.

- Repetition helps create new habits that stick.

- Starting small helps ensure improvements are permanent.

“An object in motion stays in motion” – it’s probably the most widely known quote by Sir Isaac Newton. It comes from his first law of physics, the law of inertia. It basically means that once something’s put into motion, it needs another external force to stop it.

Consider asteroids in space. Because space lacks friction,1 they travel their path continuously until they smash into something – like Earth. And having an asteroid crash into us would be problematic, that’s what scientists think wiped out the dinosaurs after all. So, NASA decided to see if there was anything they could do to help us avoid them.

Enter DART,2 NASA’s Double Asteroid Redirection Test. They created a spacecraft specifically to smash it into an asteroid. They weren’t trying to destroy the asteroid, just give it a little “boop” and see if they could nudge it off its path.

Last Fall, they identified a target named Dimorphos, an asteroid that wasn’t an actual threat, but was close enough for the test. They plowed their spacecraft into the side of it and successfully booped it off its course.

The practice test with Dimorphos proved effective. They booped the asteroid enough to change its trajectory and established the feasibility of doing this to push one away from Earth.

The small external force that NASA used to nudge Dimorphis is similar to the work done by your Continuous Improvement and Operational Excellence teams. They spend a lot of time identifying the asteroids that hurt your bottom line. They find a good target and help your team give it a little boop to improve the impact on the business.

Make sure those efforts aren’t wasted. Keep out the friction that comes from old habits and ineffective tools. Create permanent change that keeps things moving in the right direction.

Create new habits methodically

Your Continuous Improvement/Lean Six Sigma experts can help you identify where your resources are being wasted and find hidden costs in your business. They can also show you how to improve processes to remove costs. Keeping them out is the hard part.

It’s hard to eliminate old habits. It’s even harder to create new ones. When introducing process improvements to teams, you’ll need to reinforce the change over and over.

Because of the way people learn, training in a classroom or in a stand-up meeting probably won’t be enough to make a new process stick. Instead, it’s repetition that makes all the difference.

An Acadia client in consumer packaged goods reinforces process changes using multiple touch points to make new processes stick.

First, contributors are made aware of the change with an alert that requires them to acknowledge they’ve seen it and understand it.

Then, if the change is significant, the team is quizzed to ensure they’ve understood critical steps.

When they perform the procedure the next time, the digital task lists they follow have been updated with the new process, as well as video/photos/etc. that help them do it right. Managers confirm compliance by tracking task list completion.

The result of the multi-touch training means the new process is adopted faster. It’s easier to remember because of the repetition and access to tools. It also holds individuals accountable and makes it harder for old habits to reemerge.

What this has meant for our client is when they’ve identified an opportunity to remove waste, they can get it out and keep it out. They recognize the savings and then move onto the next opportunity to improve.

Since moving to the new method, they’ve surpassed Gross Line Yield goals at every plant they’ve transitioned.

Replace old tools and save even more

Waste doesn’t just happen on the front line. Even the folks tasked with pulling waste out of processes are susceptible to inefficiency.

For one of our warehouse and distribution clients, it took the Continuous Improvement manager an average of 614 hours to change a single process!

After a stand-up meeting, SOPs with the new process were produced and distributed to staff on paper. Managers recorded, also on paper, which employees were trained and had followed the SOPs. Those results were sent back to the CI manager who entered them into spreadsheets to ensure all employees received the process update. Despite all the effort, the company still couldn’t tell if employees were following the SOPs, and team members couldn’t provide feedback on the new procedure.

After converting their paper procedures to digital documents in Acadia, any new or updated SOPs are delivered to the relevant employees with just a few clicks. The system itself can identify when all employees receive them and who’s using them. This gives managers the ability to audit employees for compliance.

In less than six months, the CI manager had reduced his process change time by 90%. This allowed him to move onto other projects faster and make more improvements.

Since moving away from old tools, that one manager has helped cut outbound order shipping time by half in his facility.

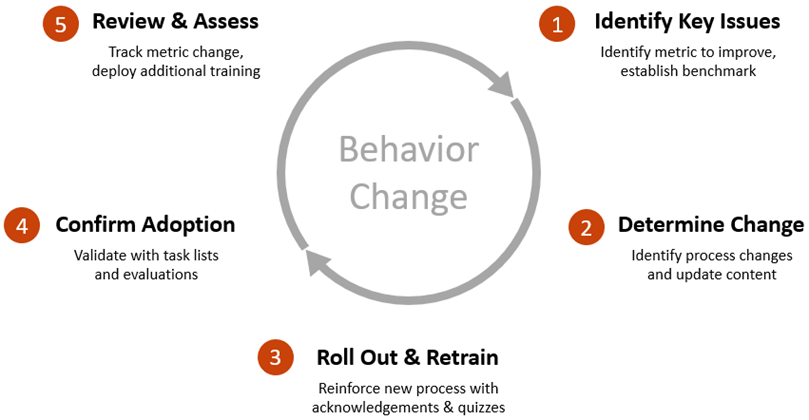

Start small and make improvements permanent

Nearly 70% of big changes fail.3 So, start small, with just a boop. But then make sure you maintain the progress you made. This is the process we follow when working with our clients:

Identify a metric you want to improve and establish a benchmark. Next, determine what processes need to change and what content needs to be updated. Then, you’re ready to implement new processes with your teams. Once you confirm your teams have adopted the new methods, you can track how your original metric has changed. You’ll know whether you need to deploy additional training or not after that.

What’s one you’d like to permanently remove? Let’s talk about it.

Sources:

Ready to crush your goals?

"*" indicates required fields