How Standard Work Checklists Improve Frontline Safety—Lessons from Van Halen

A strange clause in Van Halen’s concert contracts revealed a powerful truth: checklists aren’t trivial—they prevent failure in complex environments.

You’ve probably heard the urban legend from the 80s, about a rock star that demanded that every concert venue provide a bowl of M&Ms with all the brown ones removed. The story goes that a particular venue provided M&Ms but didn’t remove the brown ones. The rock star went berserk and then proceeded to do $80k worth of damage to the concert hall.

The story is actually true!1 But the details aren’t quite what you expect. There were brown M&Ms and that did result in $80k worth of damage, but it wasn’t the rock star’s fault. It was the venue’s failure to follow a checklist.

In 1982, Van Halen was touring the U.S., bringing with them a massive amount of sound equipment, lighting and other gear. Some of the venues they played were smaller and weren’t prepared to deal with the size and scale of Van Halen’s huge production.

Because of this, the band had a massive contract rider. It spelled out, in a series of checklists, all of the band’s requirements. It dictated the minimum size the doors could be, the amperage and voltage of electrical receptacles, and yes, buried in the middle, it stipulated that a large bowl of M&Ms be provided with all the brown ones removed. If there were brown M&Ms, the band had the right to forfeit the show with full compensation.

This wasn’t about candy—it was a system to prevent catastrophic oversights.

The reason to put so much emphasis on the M&Ms was genius. When David Lee Roth went backstage upon arriving at a venue, he would immediately check the M&Ms. If he found brown ones, he knew that the promotor had taken his contract rider too casually and they would need to double-check the entire list.

In Pueblo Colorado, the venue provided brown M&Ms, they also weren’t really sure about the amount of weight their floor could support. Before all the details could be reassessed, it was too late. The stage sunk through the floor, causing $80k worth of damage.

Van Halen, like many other organizations, found a simple solution to managing massive complexity – a checklist.

Why Experts Use Checklists

In The Checklist Manifesto, Atul Gawande shows how professionals—surgeons, engineers, aviators, and financial advisors—use checklists to prevent errors and improve outcomes.

At Acadia, we see similar impact. Our clients in manufacturing, industrial, and back-office roles use checklists to:

- Increase productivity

- Ensure consistent task execution

- Support continuous improvement

Why Mistakes Happen—and How Checklists Help

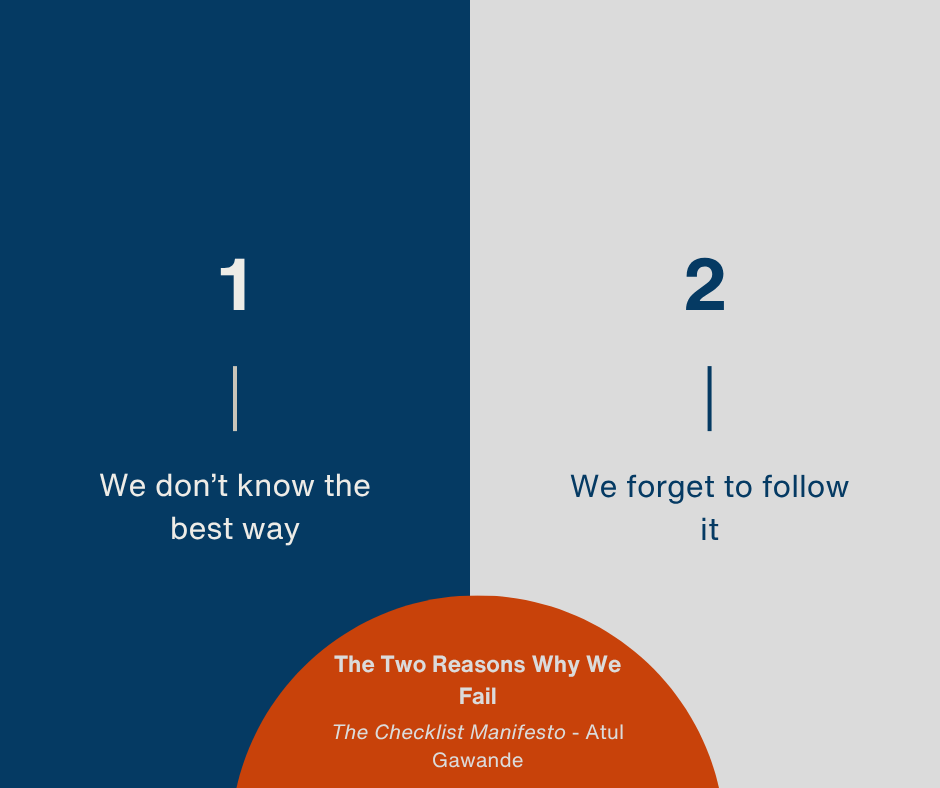

Gawande explains we fail for two reasons:

- We don’t know the best way

- We forget to follow it

Training helps, but complex tasks, distractions, and routine can cause even experienced workers to skip steps. That’s when quality and safety suffer.

Checklists act as a “cognitive net”—they catch slips in memory, focus, and attention, helping teams perform reliably under pressure.

What Makes an Effective Digital Checklist?

Today’s manufacturers are rolling out new technologies, dealing with high turnover, and facing increasing compliance demands. Checklists aren’t just helpful—they’re essential.

Checklists help with memory recall. They clearly identify the minimum steps necessary to complete the task. When developing a procedural checklist, keep it clear and concise, eliminating any ambiguity.

Finding the right balance between simplicity and effectiveness can be a challenge. Provide too little information and it won’t help. Provide too much and it won’t be used.

So, a good rule of thumb is to keep your checklist length to 5-9 items. This is the number of items a person can effectively manage in their working memory. Longer than that and people may try to take shortcuts.2

For more complicated procedures, you can join smaller checklists together into group checklists.

The most important step is to test your checklist in the real world and make changes based on what your employees are communicating back to you. Study the results your procedure generates – did it perform as expected? Make adjustments until the checklist works consistently.

How do I create a good checklist?2,3:

- Document what actually happens: Base your checklist on how tasks are performed—not on idealized or outdated procedures.

- Include only necessary steps: Focus on what’s essential to complete the task safely and correctly.

- Keep steps clear and concise: Use plain language and short phrases so instructions are easy to understand.

- Make each step action-oriented: Each item should correspond to a specific, observable action that can be clearly completed.

- Test your checklist in real working conditions: Validate your checklist by using it on the floor or wherever the task occurs. Adjust based on feedback and results.

Overcoming Resistance to Standard Work Checklists2

Some employees may resist using checklists—often viewing them as rigid or unnecessary. They may feel that checklists undermine their experience or autonomy.

In reality, checklists reduce mental load by handling routine steps, allowing employees to focus on improvement, safety, and problem-solving.

Why Resistance Happens

- Seen as micromanagement or lack of trust

- Perceived as replacing skill or judgment

- No input in checklist creation

How to Build Buy-In

Involve employees early

Let frontline workers help build and test checklists before rollout. This builds ownership and ensures relevance.

Reinforce value

Use the same checklists in training and on the job to build consistency. Highlight success stories like time savings, improved quality, or reduced errors.

Enable feedback

With Acadia, employees can flag unclear steps or suggest changes directly in the checklist. This turns checklists into tools for continuous improvement.

Real-World Results with Digital Checklists

Over the last several years, we have collected feedback from our customers on how introducing procedure task lists has helped make them be more productive. Here are just a few examples:

- Global Brewing Company: Brewery managers use digital checklists during product changeovers to maintain quality standards and reduce waste between beverage runs.

- Automotive Parts Distributor: Increased on-time outbound shipments from 40% to 80% by using standardized SOPs delivered as digital task lists to guide warehouse teams.

- Yard Management Provider: Reduced accidents and insurance claims by requiring drivers to complete a digital safety checklist before leaving the terminal.

- Medicinal Cannabis Cultivator: Ensures compliance with strict regulations by documenting every step taken by employees. Task lists create a complete, auditable trail for inspections and quality checks.

Start using modern checklists today

Need help building checklists? Get in touch with our team today!

Read on:

Is your training program hurting your process?

The reality of information overload.

Sources:

"*" indicates required fields

Ready to crush your goals?

"*" indicates required fields