Identifying Workforce Skills Gaps

Escape the pressure of a tight labor market and take skills management into your own hands

- The inability to identify workforce gaps and upskill employees could cost companies $8.5 trillion dollars in annual revenue by 2030.

- As manufacturing processes become more automated and driven by new technologies, like robotics, the demand for highly skilled team members is increasing.

- Understanding existing team member skills is critical to addressing these issues, particularly when operating within tight labor markets.

- Creating the right infrastructure can help you bridge the gap between the skills your company needs and the skills already available on your team.

- Skills Management tools can keep your team from falling further behind, while also gaining ground on current bottlenecks.

In 2011, IBM launched a high school. Yes, you read that right. The iconic technology company saw a shifting tide in the demand for workers. So, they decided to create the workforce they needed.

IBM created P-TECH, the Pathway for Technology Early College High School, to bridge the gap between an education system that was slow to adapt to the workforce need for flexible tech skills, like coding, data analytics, and manufacturing engineering technicians.1

P-TECH students graduate with a high school diploma and a no-cost two-year associate’s degree in a science, technology, engineering, or math (STEM) field. The curriculum is designed to get students ready for jobs companies like IBM will be hiring for in six years. They get in-class training, a mentor, workplace experience, and the opportunity for internships. After graduation, students can go on to four-year universities or apply straight away for jobs at IBM. They’re first in line for entry-level jobs to put their skills to the test.2

The hope is that students graduating from the school will gain a variety of skills to serve them in what IBM calls “New Collar” jobs.1 Jobs that aren’t blue collar and not quite white collar. IBM coined the term to refer to skills-based jobs that require some technical training or postsecondary education, but not necessarily a four-year degree.2

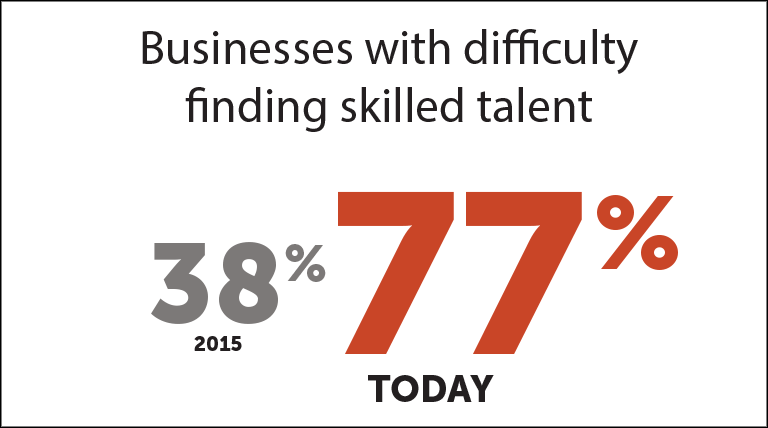

In 2018, IBM estimated a 10x gap between supply and demand for tech-savvy workers.2 Today, 77% of businesses globally reported difficulty finding the skilled workforce talent they need. That’s up from 38% in 2015.3

Some of the most severe labor shortages are for roles in digital transformation and green energy.3 (And digital transformation isn’t limited to just one industry.)

To address the problem, companies need to understand the scale of the shortage in their own business and where they need to concentrate efforts. But you need to get started now. There are opportunities to take the development of employee skills into your own hands. Obviously, most companies won’t have the resources to start their own high school. Instead, creating the right infrastructure can help you bridge the gap between the skills required by your company and the skills possessed by your available workforce.

Opportunity Cost

The opportunity cost of open positions is high. Even if every unemployed person with experience in durable goods manufacturing were employed, only 44% of open jobs would be filled. The manufacturing industry faced a major setback during the early days of the pandemic. 1.4 million jobs were lost as non-essential businesses went on pause. While the industry has largely brought back those lost jobs, they’ve only been able to fill about half of them. Companies are still seeking to fill about 693,000 open jobs.4

The retail and financial services industries are also struggling to fill job openings as well. Thirty percent of the wholesale and retail trade industry is experiencing a labor shortage. And roughly 55% of jobs in the financial industry remain unfilled.

All told, the inability to identify gaps and upskill employees could cost companies $8.5 trillion dollars in annual revenue by 2030.5

When there aren’t enough people to fill the gaps, the right tools can help bridge them. Tools like Acadia can help train employees in new skills as they perform daily activities. They can also help you assess the skills already available to you among your existing team. Perhaps more importantly, they can increase employee loyalty, improve productivity, and enhance adaptability to changing market conditions.

Where the gaps hurt most

Skills gaps have a significant impact on the manufacturing industry in particular. U.S. manufacturing is expected to have 2.1 million unfilled jobs by 2030.6 As manufacturing processes become more automated and driven by new technologies, like robotics, the demand for highly skilled team members is increasing. Yet, many manufacturers face challenges in finding employees with the necessary skills to operate and maintain them.

How skills gaps affect manufacturing:

- Lack of qualified employees – open positions remain unfilled for extended periods, leading to increased production costs, delayed projects, and decreased competitiveness

- Reduced productivity – inefficient use of machinery and technologies, errors in production processes, and longer lead times can all contribute to decreased output and increased costs

- Technological advancements – the rapid advancement of technology requires employees to have advanced technical skills or be reskilled

- Innovation and competition – skills gaps can hinder a manufacturer’s ability to innovate and stay competitive in the global market, making it difficult to keep pace with industry trends and meet customer needs

Understanding team member skills is critical to addressing these issues. You can start to build new skills when training and onboarding new hires when you can find them. You’ll likely also need to identify a path for upskilling and reskilling current team members.

Identifying and bridging the gaps

The prospect of closing such a huge gap with limited resources might seem daunting. But there are steps you can take to make sure your team doesn’t fall further behind, while also gaining ground on bottlenecks you already have.

- Define role requirements

- Track advancements in skill acquisition

- Evaluate role mastery

- Provide career path visibility

- Gain visibility of workforce skills

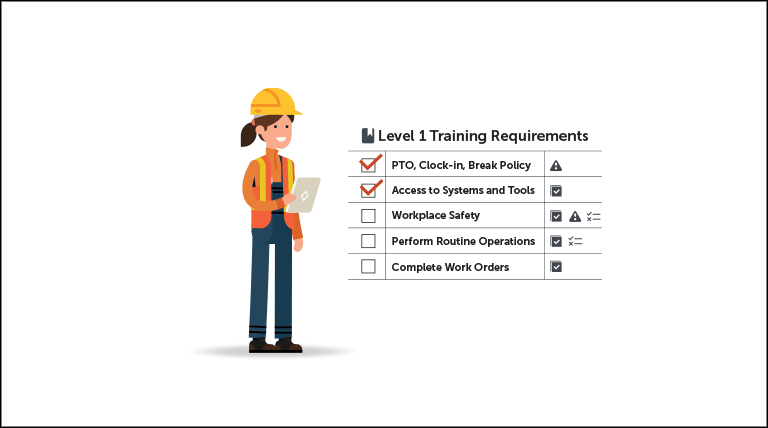

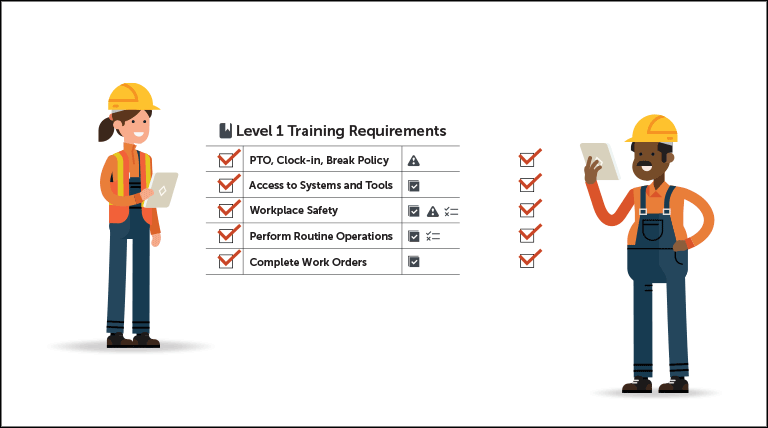

Define role requirements for each functional role on your team. In many organizations, roles also contain multiple skill levels that employees can attain by completing work. Confirm the training required for employees to operate autonomously at each level. Identify the critical procedures that need to be mastered. And outline the skills needed to transition to the next level of competency.

Create content to support your employees’ development. Focus on critical processes first and develop work instructions and job aids that help employees follow them step-by-step. The better your content, the more autonomous your teams will become.

Develop troubleshooting guides and operating manuals that include images, diagrams, and videos. These will support employee development and process improvement. The act of capturing a critical process can help you identify opportunities to improve as you go.

Track advancements in skill acquisition and make them visible to your team members. Skills acquisition may include accurately completing a procedure multiple times, passing a comprehension quiz, and acknowledging compliance of critical policies.

Making requirements transparent and providing visibility into employees’ progress against those goals helps them see where they stand and encourages self-improvement.

Evaluate role mastery on a consistent basis. This comes organically when roles are defined and all activities are tracked as part of workflow. When a team member has been trained on the job, completed procedures accurately, and been quizzed on their comprehension, a formal evaluation can help certify their proficiency.

Evaluations are a transparent way for both employees and their managers to confirm the employee’s ability to do the required work. In Acadia, evaluations are a set of requirements you can set that closely maps to critical procedures. They help guide managers as they observe and evaluate team members performing tasks.

By performing regular skills assessments, you’ll have a better idea of what skills your available workforce has compared to the skills your organization needs.

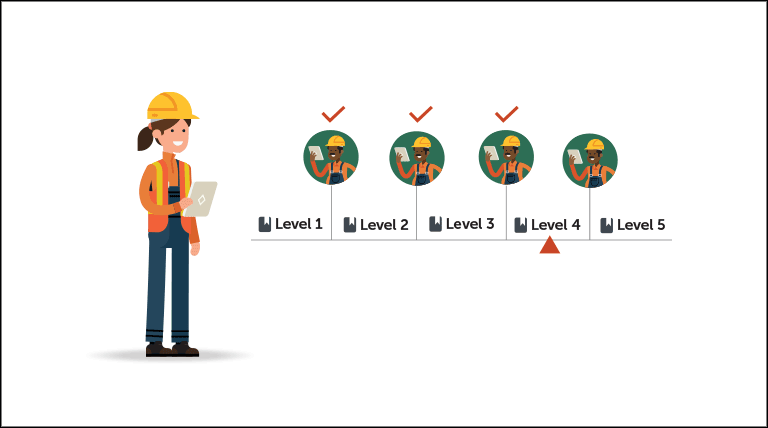

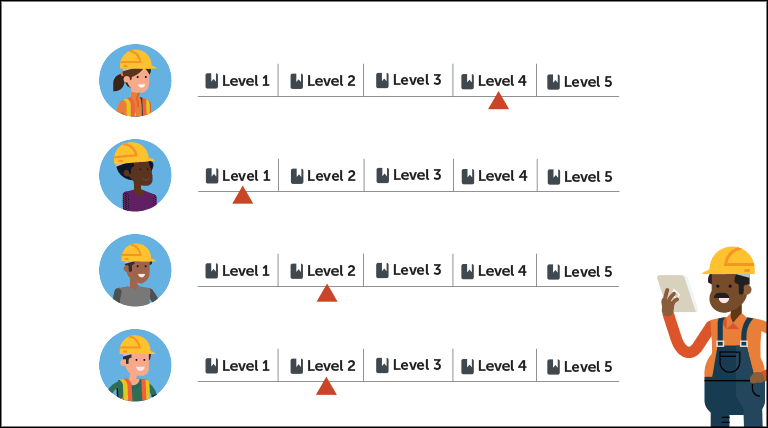

Providing career path visibility helps employees understand where they stand and what they need to achieve to advance. It creates trust and improves retention.

Your role requirements act as the guideposts for each role’s career path. Important milestones should be set to evaluate skills acquisition and should also be made clear.

A clear path for skills progression enables individual contributors to take ownership of this process. The added visibility also helps managers coach those who need it.

In a survey by Deloitte, 58% of employees think manufacturing offers limited career prospects. They would consider a future manufacturing career if there were clearer pathways for career progression and they received more personalized or customized training.5

Gain visibility into workforce skills and you’ll be able to understand and close your gaps. Most companies are currently tracking team skills and training in Excel sheets and on paper. If you’re reading this, you probably have a spreadsheet of your own. The challenge is remembering to keep these things updated.

The cost of not maintaining a current record can result in your frontline employees slipping through the cracks and missing career advancement opportunities. Your needs go unfilled, and you can lose good team members.

Instead, track training and capabilities as part of daily workflow. When team members complete a milestone by performing tasks and are evaluated for competency by managers, capture that information in one place and ideally automatically.

Skills management on the ground

One of our clients is a manufacturer of consumer goods with a highly automated facility. Their workforce is largely comprised of maintenance technicians and electricians, who keep the plant running smoothly. The company has an enviable retention rate and the original employees who started when the facility opened in the mid-1980s have only recently begun to retire. This created an immediate and alarming skills gap. Team members with 30+ years of experience were being replaced by new technicians just beginning their careers.

Because the company hadn’t experienced much turnover previously, their training program wasn’t designed for a large influx of new people. Training consisted of splitting time between reviewing manuals in the facility’s library and shadowing technicians on the floor. The library was entirely paper-based and required technicians to leave the floor in search of information. Training on-the-floor was also cumbersome. Without work instructions or job aids, they needed to wait until a machine actually broke down in order to learn how to fix it. None of this met their urgent need to replace retiring team members.

They turned to Acadia to transform their paper-based system into a dynamic knowledge repository where the entire workforce can find the information they need, the moment they need it.

Now they have a structured onboarding path with step-by-step, on-the-job training for technicians that allows them to work autonomously. Not only are their SOPs digital with videos and other job aids employees can access on the plant floor, but the SOPs can be converted instantly into trackable checklists. Tracked task lists, quizzes, and evaluations allow managers to review every team member’s proficiency in their required skills.

They’ve used Acadia to set up training paths to teach team members the skills they need. And rather than waiting for a machine to break down to show a technician what to do, they can create procedures in Acadia that help guide them through the protocols instead. It’s allowed trainers to drastically reduce the time it takes to onboard new technicians and make them an intermediate user requiring no assistance. It used to take 500+ days. With Acadia, they’ve reduced it to 125.

That’s just the benefit the company has experienced. For employees, the new system has made a world of difference as well.

One of the company’s trainers is a single father who used to be on call 24/7. Now technicians can go to Acadia to find the answers to their questions, he says he’s gotten his life back. Before, he’d have to come in on weekends if team members couldn’t remember what button to push. Now, they have the answers in the palm of their hands.

A highly skilled workforce

Another client, a durable consumer goods manufacturer, relies on a team of highly skilled engineers to perform critical procedures. Finding skilled replacements isn’t easy or cheap. Employee turnover was slowing production and creating other downstream problems. They struggled to keep shifts full and it was putting extra pressure on team members already in place. The company was losing productivity on the floor and investing heavily to identify skilled replacement candidates.

Prior to deploying Acadia, our client relied on managers manually tracking team members’ progress, capturing training milestones and skills development in spreadsheets. Employees had no visibility into how their progress was being observed or if their managers knew they were ready to be promoted. If a manager tracked capabilities incorrectly or was late to recognize advancement, they would frequently lose valuable team members.

Now, both managers and employees have gained career path visibility in Acadia. Employees track their own progress alongside managers. Both sides are aware when milestones are met, when something isn’t tracked correctly, or if a mistake is made.

Six months after launching Acadia in four plants, our client promoted 125 employees. They’re now rolling the system out to 13 additional plants.

The longer you wait, the further you can fall behind

The right infrastructure can make all the difference in your business. When employees are given the tools and autonomy to manage their own workload and career progression, it eliminates an uncertainty that can lead to employees walking away.

Skills management will help you understand every employee’s capabilities and where you have gaps. It will also help you encourage those who are close to advancing to take the next steps.

Don’t let skills gaps inhibit growth. If you’re wondering how to get started, reach out today.

Sources:

- IBM launched a high school to churn out workers for corporate tech jobs — take a look inside

- IBM’s P-Tech program integrates high school and college coursework

- 5 Numbers That Explain The Talent Gap — And What Leaders Can Do About It

- Understanding America’s Labor Shortage: The Most Impacted Industries

- The $8.5 Trillion Talent Shortage

- Competing for talent: Recasting perceptions of manufacturing

Ready to crush your goals?

"*" indicates required fields