Remove friction for your team and grow faster

How companies benefitting from the Inflation Reduction Act can reduce friction from their growth path

In 2008, Molly Graham started work at a fledgling tech company called Facebook. The company was so small at that point, she split her time between HR/recruiting and developing Facebook’s long-term mobile strategy.

Over the next four years, change became the most reliable constant in her work life. Molly’s job description was constantly shifting as the company grew from 500 employees serving 80 million users to 5,500 employees serving more than 1.25 billion users.1

As individuals’ responsibilities were taken over by teams, Molly and other leaders at the company had to learn quickly how to pass along their experience and tribal knowledge – in essence, to give away their jobs. The instinct is to try to hang onto everything to make sure nothing gets lost or broken. But that impedes progress and innovation.

Instead of trying to maintain control, Molly learned that if she could pass along information in a consistent and organized way, she had more confidence in letting go.

Today, Molly is a sought-after advisor and board member for startups in fintech, climate, education, healthcare and Web3.2 She continues to encourage people to give away their jobs to make way for progress.

If you’re one of those folks who wears multiple hats in your fast-growing organization, you may find the idea of passing along parts of your job to others stressful. Even if you hire the best possible people, it’s challenging to pass the torch without losing momentum or making mistakes.

You can overcome this and stay on track for driving profitability by establishing a single source of truth for your business. Create one place that employees can:

- Capture One Best Way policies and procedures

- Access work instructions and job aids

- Provide training and onboarding resources

- Collaborate on process improvements

- Correlate employee activity to growth KPIs

Today’s fast growers

Thanks to the Inflation Reduction Act (IRA), US manufacturers in the renewable energy sector have a unique opportunity to grow exponentially over the next several years.

By aiming nearly $400 billion in tax incentives at domestically produced sustainable energy solutions, the law is intended to accelerate the country’s energy transition away from fossil fuels.3

As a result, the IRA will also accelerate the growth of domestic producers of renewable energy, as well as the products and technology that support its adoption.4 5 Innovators in the sector that can grow and expand the fastest will capture a bigger slice of the pie.

Rapid growth will mean companies full of Mollies looking to give away their jobs. Those with the best tools will move faster. In the following sections, we identify examples of fast-growing companies and how they can remove friction from their path.

Quality assurance

The Electric Vehicle (EV) market is probably the first that comes to mind when you think of fast growing renewables companies. The new players need to create all new work forces, processes, infrastructure, supply chains, etc., just to compete in the established automotive market. As known brands add EVs to their product lines, the new players have additional pressure to compete for tax incentives.

Every manufacturer can expect some inefficiency in operations. It can be easy to miss or dismiss as part of doing business. Let’s face it, humans make mistakes; machines break down.

New companies are likely to experience more of these mistakes. Unfortunately, when demand is high, sustained downtime or worse – product recalls – are even more painful. You want your team to have the resources it needs to prevent damage and recover quickly when errors occur.

Electric vehicle maker Rivian experienced this recently when they issued a voluntary recall6 of 12,000 of the 14,000 vehicles delivered to customers7 due to a loose fastener. They are recovering well, but no new automaker wants to take the hit in wasted hours, unexpected costs, and brand damage that comes with a recall. This is particularly true for a company experiencing such high demand that the company’s pre-order backlog stood at 71,000 in July.8

Making work instructions actionable and trackable increases productivity and efficiency on the line. Line managers can identify process compliance issues and provide additional training where needed. A single source of truth also enables knowledge sharing across teams, shifts, and facilities.

An Acadia client, a global manufacturer, has been the gold standard in its industry for nearly a century. They maintain their reputation by adhering to the highest standards of safety and quality demanded by their customers.

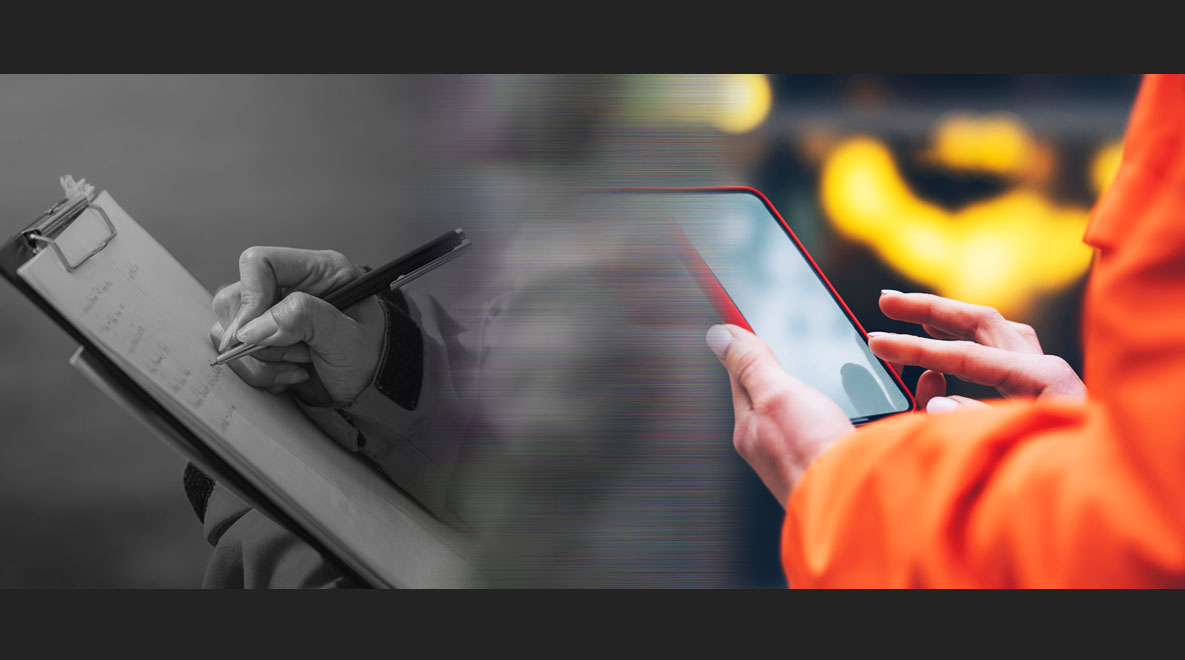

The way the company maintains such high standards and keeps customers coming back year after year is rooted in its robust audit process. A problem they noticed was that as audits became more robust, managing their own standards as well as the individual requirements of each customer became increasingly complex.

The main source of complexity was the volume of documents needed to perform audits, as well as the process used to store, update, and review them. The company made the move from paper to digital and scored their first of many 100% audits with far fewer people hours.

Outcomes

- Consistent audits in the 90-100% range

- Reduced waste and recalls

- Improved customer satisfaction scores

As the company expands its replacement of paper tools with digital across the globe, the company continues to see a decline in wasted product and people hours. They’re also hearing a lot of positive reviews from their customers.

Scaling

Concerns about quality are just the tip of the iceberg for fast growing companies. Hiring new employees, expanding facilities, and adding automation all require time and attention. The faster you can master these new tasks, the sooner you can get to profitability.

First Solar is in that position and is already making moves to benefit from the IRA. The company manufactures solar panels using thin film photovoltaic (PV) modules, providing a competitive, high-performance, lower-carbon alternative to conventional crystalline silicon PV panels.9

Companies looking to adopt renewable energy and benefit from the IRA will need to source their materials from the US to qualify. And First Solar is one of the only U.S.-based companies with exclusively domestic manufacturing operations. Anticipating higher demand, the company is opening a third factory in the first half of 2023, and a fourth in 2025. They’re also expanding their operations in existing facilities.10

Adding new facilities means onboarding new employees and upskilling others. But some traditional methods for training and onboarding have been proven not to work. By using single-source-of-truth content during the training process and making it available on the factory floor, the company could streamline training and get their new facilities operating at capacity sooner.

Training that sticks

Beginning in 2017, another Acadia manufacturing client began to incorporate work instructions into its training program. Starting in the classroom, new hires were exposed to the exact materials they’d have available to them on the floor.

When the new team members joined their colleagues in production, they knew where to go when they got stuck. They could find the job aids and other information they needed to do their work accurately.

Not only did this result in a faster path to productivity, it also led to less wasted hours by senior staff who would traditionally need to work shoulder-to-shoulder with the new folks.

Outcomes

- Each plant that incorporated Acadia exceeded Gross Line Yield (GLY) within the first 6 months

- SOP compliance was higher and correlated directly with GLY

- Quality, safety, and waste metrics all improved as more employees gained access

Correlating employee SOP compliance with KPIs that drive their stock price was a revelation for our client. By continuing to add more processes and employees to the system, they could tackle other goals across operations.

Downtime reduction

Unplanned downtime is one of the most frequently occurring and costly of the self-inflicted wounds any manufacturer can make. It’s also one that can be minimized through better training and preparation.

Storing energy created by renewable sources has become as critical a challenge to solve as generating the power. American Battery Factory (ABF) focuses exclusively on manufacturing and enhancing high-performance Lithium Iron Phosphate (LFP) batteries. The company is anticipating such high demand for its product that it’s designed a “factory-in-a-box” model to rapidly deploy additional production capacity as needed.

If demand reaches levels that require the company to launch new facilities so quickly, any improvement to uptime should drop immediately to the bottom line.

The IRA is already helping American energy storage technology and manufacturing company Form Energy bump up their timeline. Form Energy’s goal is affordability. They’ve been working to build something that would work as well as a lithium-ion battery at one-seventh the cost. To build a 100-hour battery, they rely on a dirt-cheap, abundant element – iron.11

The company anticipates bringing their iron-air battery to full commercial deployment in the next two years. Avoiding downtime during that period will be essential. They’re also anticipating a large hiring spree in West Virginia and Pennsylvania. Removing barriers to uptime should keep them on schedule and reduce wasted time and money.

Because unplanned downtime is almost always attributable to human error, training and preparedness are your best tools to eliminate the impact. Reaction plans are a simple solution to help teams troubleshoot unplanned downtime. But you can find more immediate savings by improving planned downtime.

Every minute count$

Improving planned downtime can mean millions of dollars saved across the enterprise. Our client, a global consumer durable manufacturer, learned recently that improvements can happen quickly with the right tools.

Operations leaders understood that shaving even a few minutes off their downtime would generate significant savings. With a complex process and frequent operator turnover, the team needed a better way to ensure their downtime process was executed accurately each time.

Continuous improvement managers at one plant replaced traditional shoulder-to-shoulder training with a more consistent and repeatable process in Acadia. Each team member was required to read and acknowledge a document containing the proper preparation and execution of the procedure. Then, they were quizzed on the information.

Finally, they were observed and formally evaluated while executing the procedure live. All of this information was tracked in Acadia to identify team members who needed additional support and which aspects of the process needed reform.

After only two weeks, the team was able to improve their downtime by 19%!

Outcomes

- 8 minutes improvement and $500k cash savings due to decrease in error rate, rework, and unplanned downtime at a single facility

- Reduced time to proficiency for new hires and existing employees

- Higher retention rate of skills among those trained using the new method

This common procedure takes place at many of our client’s facilities and requires planned downtime 20-30 times per day. At one of their largest facilities, it happens up to 60 times per day. When implemented across all plants producing the same products, their savings will be in the millions.

Start sharing

Regardless of what growth phase your business is in, supporting your frontline team members will make them more productive and your business more profitable.

If you’re having trouble identifying a place to start, let’s talk about it.

Sources:

- “Giving Up Your Legos” and Other Lessons in Scaling

- Hi! I’m Molly

- An Overview of Clean Energy Tax Legislation in the Inflation Reduction Act

- Fact Sheet: IRA EV Tax Credits

- Summary: The Inflation Reduction Act of 2022

- Rivian has fixed a ‘significant majority’ of its recalled vehicles

- Rivian is Facing a Recall of Almost Every Vehicle it has Sold. The Company’s Response is a Master Class in Handling a Crisis

- Rivian lays off 6 percent of its workforce as it struggles with EV production

- Leading the World’s Sustainable Energy Future

- The Largest American Solar Panel Maker Pledges to Build $1B Factory in US Southeast [Update]

- Why Rust is the Future of Very Cheap Batteries

Ready to crush your goals?

"*" indicates required fields