Agility: your best response to tariff-driven change

Make it easy for your team to adapt to change under challenging conditions.

There’s been no shortage of commentary on the potential economic outcomes from the recent trade directives coming out of Washington. Whether you think it will help or harm the US industrial sector in the long run, everyone seems to agree that there will be a lot of uncertainty in the interim.

In 2018, new tariffs drove many to consider reshoring (or at least nearshoring) some production from China to North America. Others reacted to counter tariffs by moving operations to Europe and other territories.1 The pandemic in 2020 pushed companies to further diversify their supply chains and develop new assets domestically.

Now, with tariffs levied across the board, even the penguins aren’t immune,2 much less our neighbors to the north and south. Despite the United States-Mexico-Canada Agreement (USMCA), a new 25% tariff on Mexico makes near-shoring more complicated.3 Onshoring isn’t feasible for many either because the capacity or capability doesn’t exist here anymore4 and could take decades to rebuild.

While new tariff policies and ensuing market conditions continue to shift, it’s important to assess your vulnerability and develop thoughtful contingency plans – both downside and upside.

But don’t stop there. Your plans are only as good as your ability to implement them. Make sure you can communicate your strategy to employees and guide them through day-to-day challenges. Perhaps more importantly, ensure the change persists after your training exercises have run their course.

Communicate early, often, and consistently

Uncertainty can lead to fear and employees will look to leadership for a plan to get the team through this period. Whatever plan you deploy, it almost certainly won’t be business as usual. Employees will need to quickly learn new policies and procedures. You won’t want to waste time trying to figure out who’s heard about the changes and whether they’ve adopted them.

Change management is largely a messaging exercise. Develop a communication strategy designed to achieve distinct objectives and take care to ensure the message finds its target. Here’s how to educate employees about changes you want them to make:

- Ensure you reach each group of employees with a message that’s relevant to them.

- Make sure they have seen and understand what’s expected of them.

- Describe how the change benefits them and engages them in being part of making it a reality.

- Communicate frequently with updates and deliver the message consistently over time – sharing progress, wins, and losses.

- Celebrate the people who have adapted the fastest or gone above and beyond to make the change smooth for others.

Each of these messaging components plays a role in change management. But combined, they are more effective than the sum of their parts.

Ensure employees know their responsibilities

Communicating your plan to employees is a good start. But what do you need from individuals? Depending on your business situation, you’ll be requesting teams and individual employees to change the way they work.

You can start by outlining new policies like changes to procurement guidelines, billing requirements, or production procedures and sending them to the appropriate employee group. Ensure employees have read and understood the new policy by requiring them to acknowledge it .

For mission critical aspects of your procedural changes, quiz employees on new information. It will help them remember and make your change stick.

Guidance and reaction plans

As you get into the day-to-day execution of your updated strategy, you’ll need a way to guide employees, ensure they’re following new processes, and provide a means for making additional changes.

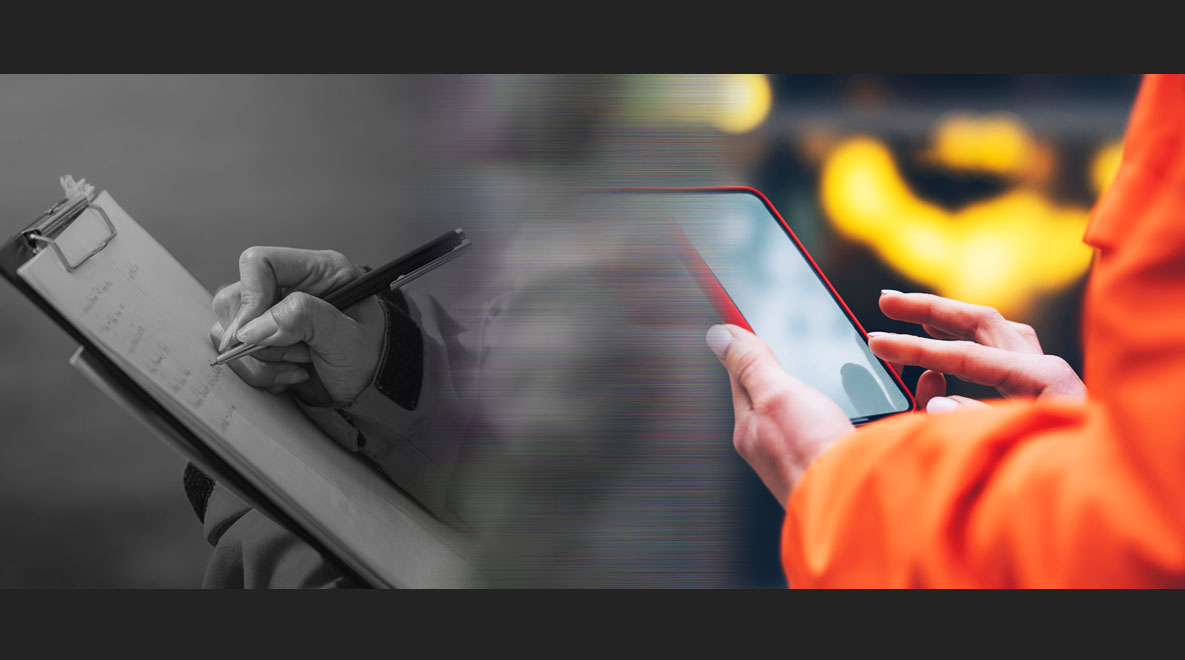

Deploying digital work instructions to your team will walk them step-by-step through a new procedure. It will also provide a view into their compliance with standard work, helping you target additional training where needed.

Assuming you don’t get everything perfect on the first pass, you’ll want a way to quickly pivot. Providing work instructions electronically also makes it possible to get their feedback and make improvements instantly available to your team.

The natural next step is a cycle of deploying standard work, capturing feedback, improving processes, and tracking progress against your goals. That’s when change becomes permanent and easier to implement with the next disruption.

Progress and outcome visibility

Navigating disruptive change is even harder in the dark. Visibility into employee training, adoption, and compliance of new processes is critical. Training shoulder-to-shoulder, delivering work instructions on paper, and tracking employee capabilities in spreadsheets are all time-consuming activities. They limit your ability to quickly understand what’s going on in your business.

In Acadia, all the capabilities described above are seamlessly deployed and provide reporting that helps you navigate change nimbly. Reach out, we’ll make it easy for you to manage through the current turbulence.

Proven, Lasting Change

Here are a few examples of change projects we’ve helped Acadia customers work through. The best part is, in every instance, the change stuck and continues to benefit the organization.

$500K savings in downtime improvements

- Savings due to process change that led to decrease in error rate, rework, and planned downtime at a single facility

- Reduced time to proficiency for new hires and existing employees

- Higher retention rate of new skills among those trained using the new method

600 employees reskilled in just a few months

- Increased efficiency to double the number of pallets packed/hour

- Rapid adoption of new technology with virtually no downtime

- Reduced travel waste & Improved pick rate

72% reduction in failed duty assignment audits

- 33% reduction in adjustment costs from failed audits

- Decrease in compliance errors and customer disputes

- Improved time to compliance for new regulations and duties

Exceeding Gross Line Yield Targets within 6 Months at Each Plant

- Employee SOP compliance directly correlates with target outcomes

- Employee engagement and SOP compliance drive continuous improvement

- Best practices tied to KPIs are shared globally

Sources:

- Harley-Davidson warns European tariffs will cause a ‘tremendous cost increase’

- ‘Nowhere on Earth is safe’: Trump imposes tariffs on uninhabited islands near Antarctica

- A new tariff paradigm: How businesses can respond

- The Puzzle of the All-American BBQ Scrubber

- How to Communicate Organizational Change: 4 Steps

Ready to crush your goals?

"*" indicates required fields