Double-down on Performance Improvement to Get your Budget Approved

5 steps to confidently incorporate ROI and efficiency gains into your planning

- Results are most often achieved by doing what everyone already knows is the right thing to do but only a few are actually doing.

- Capture the knowledge of your top-performing employees and turn it into digital work instructions before looking outside the organization for the big solution.

- Use tools like checklists and evaluations to determine who’s following your One Best Way and who needs more training support.

- Recognize small achievements along the way to add fuel to the fire.

Year-end budget talks are a crucial time to make strategic decisions. It’s kind of like a high-stakes poker game.

Each player (department) is carefully calculating their moves. The chips on the table represent budget allocations, and everyone is trying to come out with the best hand (financial plan) to secure a winning outcome for the next round (year).

But unlike poker, you don’t have to leave your cards to chance. Connected worker platforms, digital work instructions, and skills management may still be relatively new ideas for many industries, but you can play your hand wisely with data and insights that validate significant ROI and efficiency gains.

Where to begin?

Complicated business processes can easily become bloated, inefficient, and expensive. Lean and Continuous Improvement experts are deployed to identify and implement changes to cut the fat. For some companies, the tiniest changes can add up to huge efficiencies, eliminating waste, and delivering cost savings.

But where to begin? Many Lean practitioners will begin by walking the floor, observing work being done, and speaking with frontline team members. While observation is a good place to start, how do you implement and ensure your teams can carry out those changes?

If you follow the 5 steps below, you may be able to skip ahead and get to an answer faster.

People typically think that you need to fix your culture before you can effectively deploy a successful business strategy. But fixing your company’s culture? That sounds practically impossible.

Instead, Peter Drucker, the management consultant and educator who is widely considered a founding father of modern business management, has said:

“Culture – no matter how defined – is singularly persistent.”

Meaning that results are most often achieved by doing what everyone already knows is the right thing to do but only a few are actually doing.

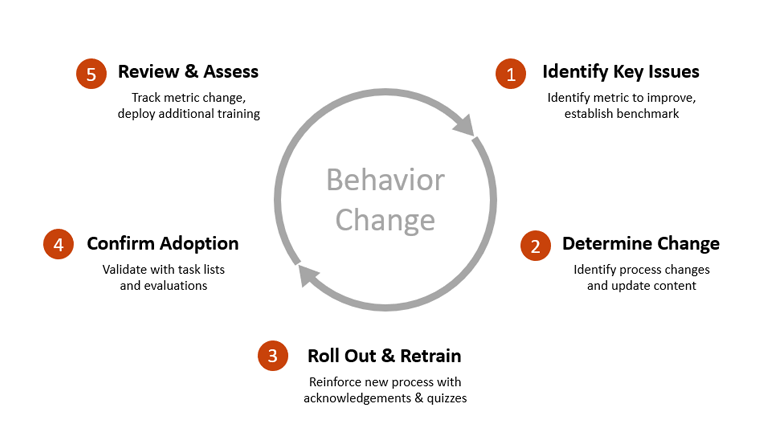

Drucker went on to describe the path to behavior change – and reaching your business goals – that anyone can achieve in a few short steps:

1. Define the results you need to hit

You can use any metric/goal/KPI that your team is working toward to validate the expense of software in end-of-year budget talks. We’ve helped our clients:

- Reduce downtime on a common procedure that happens up to 60 times a day, saving 8 minutes and $500k

- Improve new hire time to proficiency by 77%

- Improve ratings from your customer service response

- Increase outbound order accuracy and picking processes at your warehouse

- Improve O2C process execution resulting in millions in savings

- Exceed gross line yield targets withing 6 months at each plant

The metric itself is almost irrelevant. It only matters that you can establish a benchmark against which to improve.

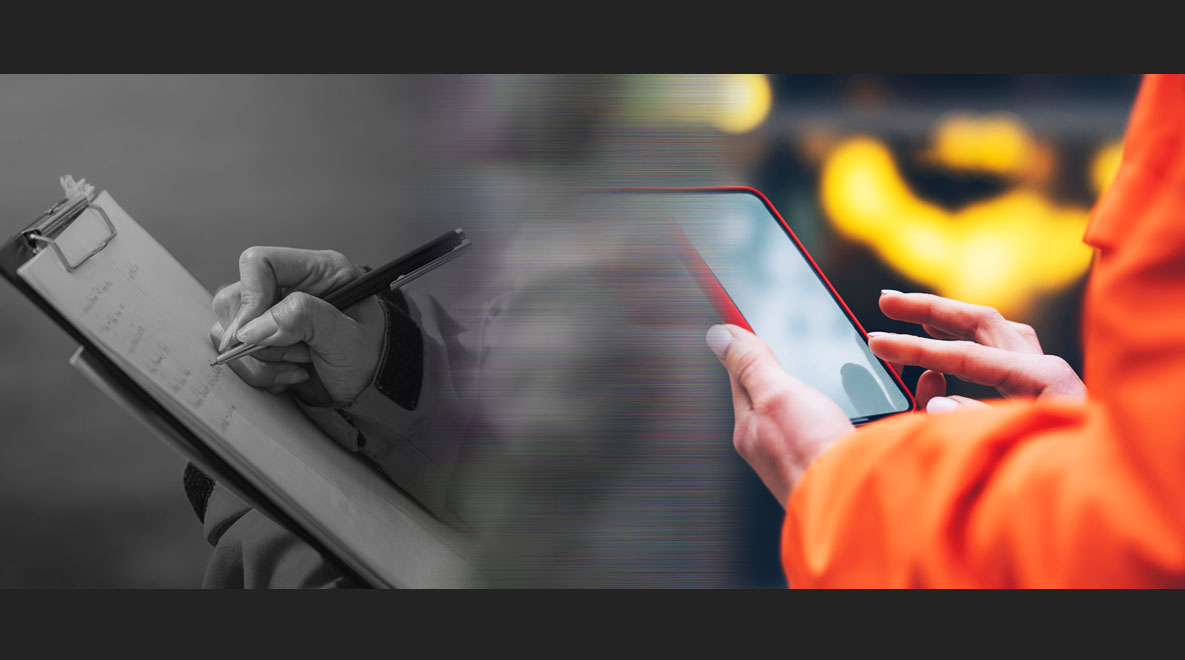

2. Identify where you’re already doing this in your business

It’s possible that the One Best Way process already exists in a binder that sits on your desk, where it’s not taken advantage of. Maybe it’s printed out and attached to the side of a machine. What we’ve seen most often is that it’s engrained in the minds of your top performing employees where it can’t be accessed easily by others.

What we often fail to do is identify best practices and put them to use. Instead, we turn to industry experts to advise us on how we can improve our own One Best Way. We look outside the organization for the big (and usually expensive) solution that will solve all our problems when what we’re looking for may very well already be in the heads of our top-performing employees. Instead, we should turn our gaze inward, identify incremental improvements already being used, and spread them across the enterprise.

If you can capture that knowledge and turn it into digital work instructions, your teams will be set up for success even when your top performers retire. You’ll increase the time and proficiency for onboarding and training new employees as well.

3. Make sure management is reinforcing the proven, effective behavior

When you identify The One Best Way, you can print it out and pass it around to everyone. You can tell your teams about it in a stand-up meeting or send an all-hands email. But that probably won’t do much to change anyone’s behavior.

Or, you can train everyone on the right way, validate they know how to do it, and ensure they can easily reference the One Best Way every time they go to perform the task.

4. Change habits and behavior through recognition and rewards

Ensuring your teams have access to the One Best Way doesn’t guarantee they’ll follow it. Use tools like checklists and evaluations to determine who’s following it and who needs more training support.

When everyone’s on the same page, your teams will start hitting their goals and that should also mean everyone is earning their compensation incentives.

As you work toward these goals, recognizing small achievements along the way can add fuel to the fire. As soon as your team members realize they’ll be recognized for the right behavior, they’ll be more inclined to repeat it. Even if the recognition is just a pat on the back in a group setting – these acts of encouragement go a long way.

5. Reassess, repeat

This one didn’t come from Peter Drucker, but we suspect he’d approve.

After a short period of time, with everyone following The One Best Way, check your progress against your benchmark and make the next improvement. Once your team has been through this cycle a couple of times, you’ll find they can handle more changes at a faster rate.

To find the next opportunity to cut costs, improve efficiency, or beat your quarterly goals, go back to step one and start again.

Here’s a simple chart we use to help our clients adopt this process:

A real-world example

We run this process with our clients frequently. Getting a pilot started as a proof of concept helps to tease out the real problem they’re trying to solve and identify pragmatic solutions to solving them.

For an Acadia client operating in the flooring industry, a common procedure requires planned downtime 20-30 times per day at each of their facilities. In one of their largest plants, it happens up to 60 times per day.

Of course, every minute of downtime means dollars lost. The longer and more frequent the downtime, the less product is shipped. But with a complex process and frequent operator turnover, our client needed a better way to ensure their process was executed accurately each time.

Enter Robert, a Continuous Improvement leader working on an underperforming line. He replaced traditional shoulder-to-shoulder training with a more consistent and repeatable process delivered at the point of use in Acadia.

Each team member was required to read and acknowledge the proper preparation and execution of the procedure. Then, they were quizzed on the information. Finally, they were observed and formally evaluated executing the procedure live. All of this information was tracked in Acadia to identify team members who needed additional support as well as aspects of the process that needed reform.

After just two weeks of training using the new method, the team had already improved their unplanned downtime by 19% and reduced product waste. They’ve since taken those same work instructions and are implementing them across all plants producing the same products. When complete, the savings will be in the millions.

So what’s 8 minutes worth?

The team saves $500,000 by bringing their procedure time down from 15 minutes to 7.

The concepts used to deliver these results aren’t complicated, time consuming, or expensive. In fact, they’ve been around for years. More importantly, they already exist in your organization and just need your help to be exposed and leveraged.

Don’t allow perfection to get in the way of improvement

With a few simple tools, you can tap into an infinite resource of process improvement that already lives in the heads of your team members.

Get started with a single project, on a single team. Then use those results to lead to your next improvement goal. Doing so can improve your business outcomes, the engagement you have with your teams, and help you maximize your ROI.

Reach out to us, we can help you get there quickly.

Sources:

- Drucker Institute: Did Peter Drucker Say That?

- Don’t Change Corporate Culture – Use It!, Peter Drucker, The Wall Street Journal – March 28, 19

Ready to crush your goals?

"*" indicates required fields